Not everyone enjoys the lack of monolith in the tiled interior. The desire to get rid of seams and bring the canvas closer to a monolithic ideal brought to life the technology of rectification - the final processing of the edges of the plates. On a special machine, granite, pressed and fired, is deprived of chamfers. As a result, the facing material gets a clear rectangular geometry and butt-to-butt laying is allowed.

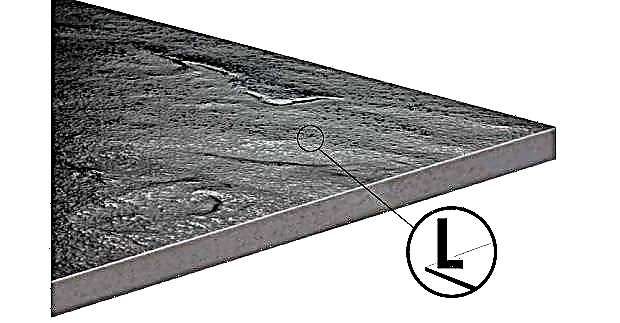

The faces of rectified tiles undergo additional mechanical processing.

The box with tiles always indicates whether it is rectified.

The world is imperfect, and rectified porcelain stoneware also leads to polar consequences. Next, consider the advantages and disadvantages of seamless technology.

Pros and cons of rectification

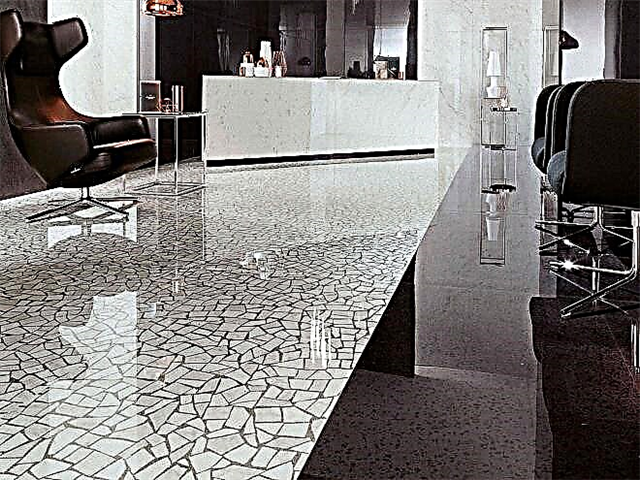

Travertine tile collection Millenium Concept, Porcelanosa (Spain).

- Aesthetics. Seamless styling looks in many cases much more beautiful.

- Lack of dirt, fungus and mold in the joints.

Among the minuses:

- The complexity of the lining.

- Limited temperature operation and an insufficiently wide range of places where rectification is possible.

- The restrictions imposed by the curvature of the tile plane.

Now about each of the items in more detail.

Difficulty facing

Unfortunately, seamless styling is more time consuming. Normal cladding involves a “game” with seams, the gaps hide not only ceramic flaws, but also the possible inaccuracy of the tiler's manipulations. When working with rectification, all actions must be carefully verified. In the most “tough” case, the tiler does not have a stock of treasured millimeters for maneuvering with tiles. Although the processed boards themselves make the work easier - there is no need for additional calibration (apart from tonal), no need to worry about the accumulation of dimensional discrepancies.

Temperature and zone restrictions

“Floating” tile dimensions are not the only reason for the installation of joints. The gaps protect the tiles from temperature fluctuations causing deformation of the adhesive or mortar. Microscopic displacements of the mixture are sufficient so that in many situations a dense contact of the plates is undesirable. Seams provide a margin of potential ceramic motion.

In addition to thermal differences, displacement is caused by shrinkage of the house and seismic activity. Do not think that only new buildings are subject to shrinkage. To one degree or another, the house shrinks throughout the “life”. Yes, several years after construction, the rate of shrinkage is reduced, but the movement does not stop completely. The same applies to building structures located in seismically active zones or near quarries.

Rectified tile Cersanit Ariva (Poland) 29x59.5 cm.

Plate plane effect

Relying on cropped edges, many forget about another dimension. Leaving the oven, the tile does not have strict geometry, but only edges are processed at best, the plane of the canvas remains untouched. Meanwhile, the curvature of the front of ceramics is an eternal problem for tilers and consumers. High-quality tile has very small horizontal flaws, but they are. The seams smooth out the flaws, but the rectification reveals the problem.

Seamless ceramic tiles are possible only in the case of a miniature "propeller" and, preferably, subject to additional calibration. In other situations, it is recommended to make narrow seams.

Rectification Facing

Seamless tile - a godsend for esthete. Despite limitations, the end result is worth the effort to overcome the effects of negative factors. The rules for facing with cropped tiles do not differ from ordinary ones. But adhere to certain standards:

- Prepare the base very even. To play with the shrinkage of the rectified, and it is usually dimensional, not easy. It is much easier to lay in an even layer, but the latter is possible with an ideal surface. The same thickness of the glue is also important from the point of view of the reaction of the mixture to temperature fluctuations, uniformity positively affects its adequacy.

- The base must be strong. This means: only concrete or cement-sand coating. No drywall, wood, or other unstable materials.

- To trim a large rectification you need to have a professional manual tile cutter with an elongated bed or separate guides.

The Rubi Slim Easy system has long guides and separate cutters for cutting tiles of any format.

Tile suction cup holder from Litokol.

The apron and countertop are lined with seamless porcelain stoneware. Holes for sockets, trimming and burrs were made using waterjet cutting.

- Laying porcelain tiles on the floor: technology from A to Z

- What is clinker tile? Pros and cons, use and styling

- Stone and brick decorative gypsum tiles: pros and cons, laying and manufacturing

The main differences between seamless and regular tiles

The main differences between seamless ceramics and traditional tiles are:

- production process

- styling technology

- design design

- application area.

Seamless (rectified) tile is made in a special way, which leads to its dimensional standardization. This allows you to create a visible coating integrity when facing. Obtaining dense laying of granite to each other succeeds in rare cases. Often between the tiles there is a gap of 1.5-2 mm.

In the serial production of ordinary tiles, small geometric inaccuracies and unevenness in size arise due to the lack of standardization of elements. Permissible calibration of products may be 4-5 mm. This disadvantage of ceramics is easily leveled with the help of traditional technology of facing the surface with the specified building material with the device of tile joints. The uniform thickness of the joints between the tiles is achieved by using special devices - plastic crosses.

This type of colored ceramics in combination with contrasting tile joints can create interesting varieties of compositions in the interior decoration of the room.

Production technology

Ceramic seamless tile, designed to obtain a monolithic ideal surface during cladding, made by rectification technology. The rectification process is an additional alignment of the edges of the finished tile with diamond cutters on high-precision equipment.

Compressed and fired porcelain tiles to give an even rectangular shape undergoes ideal cutting of faces and edges on a special machine. As a result of rectification, it becomes possible to create a seamless surface, further laying tiles joint to joint.

Advantages and disadvantages of using

Rectified porcelain stoneware in use has the following advantages:

- creates an aesthetic appeal visually representing an expensive monolithic stone surface,

- helps to reduce the inter-tile space, where dirt and pathogens often accumulate,

- there is no need to purchase grouting and work on the installation of tile joints.

The disadvantages of ceramic seamless tiles include:

- the complexity of laying associated with a careful fitting of the material, high-precision actions of the tiler,

- the negative effect of temperature changes on the service life of this facing material,

- limited range of applications

- roughnesses of the front surface of the plates, leading to additional difficulties when working with them.

The question of the use of seamless porcelain is solved taking into account the consideration of the advantages and disadvantages, the quality of the material, the specifics of the base.

Features of the surface facing rectified tiles

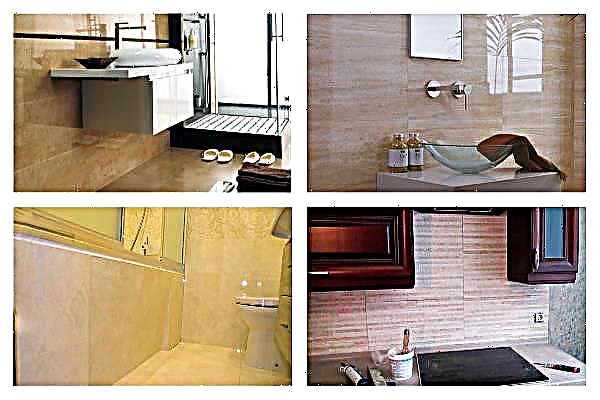

Rectified large porcelain tiles are well suited for seamless wall cladding of walls, ceilings, and floors.

First, a perfectly flat and durable surface should be prepared for laying. For seamless porcelain stoneware, only a concrete base is used. In advance, you need to take care of the presence of a tile cutter and special devices - suction cups.

Installation of seamless ceramic tiles requires high precision styling, diligence and diligence of the master. A compensation seam with a width of at least 1 cm must be made along the perimeter of the room. Careful marking is carried out.

It is important to apply a uniform layer of glue to each facing element in order to avoid the formation of voids and as a result of material damage.

Tiles are stacked in rows with high accuracy, a slight deviation from which will lead to irreparable consequences. Laying the material on the walls and ceiling require special skill. In the formation of an inter-tile seam (1-1.5 mm), an epoxy grout is used.

Where is better to use?

Rectified porcelain stoneware should be used only in rooms subject to the conditions:

- constant temperature of the environment, without sudden changes,

- lack of seismic activity,

- with minimal shrinkage at home.

Seamless tile on the ceiling or floor will not work:

- in a bathroom or kitchen with high humidity,

- in new buildings with an active shrink process,

- in houses located near quarries due to ground movements,

- in living quarters with equipped underfloor heating.

In the bathroom of a small area, you can pick up large porcelain stoneware for the floor.

The manufacturer warns against using this type of facing material as paving stones for garden paths, terraces, verandas and other outdoor amenities. Does not guarantee a long service life and paving seamless tiles.

Rectification technology

How often do you want to get a monolithic coating of tiles, but with ordinary material this is impossible. It is for those who want to have a monolithic ideal coating and rectification technology has been developed, which consists in the final processing of tile edges. This technology is used for ready-made porcelain tiles, which have passed the stage of pressing and firing. With the help of a special machine, chamfers are removed on such tiles. And as a result, porcelain stoneware has a clear rectangular shape, which makes it possible to perform joint-to-joint laying.

Laying seamless tiles does not guarantee a complete absence of seams. When a composition consists of individual elements, then counting on the perfect layout would be naive. Using rectified porcelain stoneware this problem is solved, the integrity of the coating is much better. Therefore, edged ceramics are finding more and more fans.

It is worth noting that the so-called seamlessness ranges from the complete absence of seams to laying with small gaps, the maximum size of which does not exceed 1.5 mm. But if the lining is performed with a standard tile, then such a width will be unattainable, precalibration will hinder.

In this world, there is practically nothing perfect, so the use of rectified porcelain stoneware can also have quite unexpected consequences. Today we dwell in more detail on the pros and cons of seamless tile laying.

The advantages and disadvantages of rectification

Indisputable advantages include:

- Aesthetic side. Stacking without seams has a more attractive appearance.

- There are no joints, therefore, respectively, and the place where the dirt is collected, fungus and mold are formed.

The disadvantages of the rectification process are expressed in:

- The complexity of facing.

- Limitations on the temperature at which this type of cladding can be used and the range of places where the rectify are laid is not too large.

- Limitations that arise due to the curvature of the tile plane.

Now let us dwell on these points in more detail.

Outward appeal

If so, then stitches are just a necessity that needs to be taken for granted in almost all cases. Monolithic cladding, which has no joints at all, is an ideal solution for which ceramic tile manufacturers work tirelessly. Using rectified porcelain stoneware is a great step towards the top. Correct cladding with minimal joints looks much more attractive than its counterpart with traditional tile joints.

Mud fight!

Seams are just a super place to attract not only dirt, but also fungus. If you use high-quality grout, you can be sure that these troubles will bypass you. But unfortunately, a good grout is usually quite expensive, so not everyone can buy it. And then the density of ceramics is much higher than the best putty.

A tight junction does not mean that it does not exist at all, so even foreign objects can get into these microscopic gaps, although seamless laying minimizes all their efforts.

But even the most perfect creature has its drawbacks. There are those in our cladding without seams.

The complexity of the facing process

Seamless styling can not be called easy, it is even more time-consuming than traditional. With ordinary cladding, it is possible to adjust the seams, because with their help not only the errors of the tile are not so noticeable, but also the flaws in the work of the tiler. Work with rectified tiles requires special care. The most difficult case is the complete absence of extra millimeters, which are sometimes necessary for a successful maneuver with tiles.

Although it is much easier to work with processed plates, you do not need to perform additional calibration, except with a tone. There is no need to ensure that dimensional differences do not accumulate - they simply do not exist.

Temperature and place of use

The discrepancy in the size of the tiles is one of the main, but far from the only reason why tile joints are needed. The gaps serve to protect the tiles from temperature extremes, due to which deformation of the adhesive or mortar mixture occurs. Even due to the microscopic displacement of the adhesive, an unwanted contact between the tiles occurs. The seams are designed to provide the tile with potential movement.

In addition to temperature changes, displacement can occur due to shrinkage of the house or seismic activity. It is a misconception that only recently built buildings are seated. This process is characteristic of all buildings, and throughout their operation. The rate of shrinkage can only slow down, but not completely stop. The same problems are also characteristic of buildings located in seismic zones or near quarries.

Of course, you can choose a seamless tile, but only taking into account all the individual characteristics of your building. It’s not worth repeating, but still I want to emphasize that rectified packing is possible only when the room temperature is constant, without sharp fluctuations. For this reason, it is not suitable for a warm floor.

Or you will have to slightly deviate from the rules and make minimal seams with a size of 0.5 to 1.5 mm. An ordinary tile such a cladding still cannot be completed, so the cost of a seamless cladding is worth it. Seams of several millimeters can be a real way out - they will help to cope with temperature extremes and will not spoil the resulting image at all.

Rectification

Seamless styling is very beautiful and aesthetically pleasing.Despite all the difficulties and limitations in its arrangement, upon completion of the work you will be satisfied with the result, because it is worth it.

The trimmed tile is laid in the same way as usual, but in this case it is necessary to take into account some nuances:

- The base should be just perfectly flat. It will be much easier to lay, which forms an even layer, and this is possible only on a very well prepared surface. It is necessary to apply glue with the same layer over the entire plane, so you can get the same reaction to temperature fluctuations. In general, the smoother the layer, the more adequate the reaction.

- A very important factor is the strength of the base, so laying is performed exclusively on a concrete or cement-sand base. Wood, drywall and other unstable materials are completely excluded.

- Manually cutting a large rectify will not work. Have to acquire a professional tile cutter with an elongated bed or separate guides.

- Another interesting device that can be used when working with seamless tiles is suction cups. Thanks to this invention, the laying of tiles is greatly simplified, it is easier to press, without contacting the adhesive.

- To grind seamless tiles, you need a wet cutter. For the long side of the tile you will have to use a grinder and a diamond blade. To finish the seam, you need a diamond chalk and flexible grinding wheels - turtles.

- If, nevertheless, the laying is with minor seams, you can use the blades from the construction knife. Their thickness is small, so it is just suitable for minimal seams. If the seams are 1.5 mm, then ordinary plastic crosses will come to the rescue.

- If you still managed to completely do without seams, then the grout is no longer necessary. If there are still seams, then proceed to trowelling (for more on this in the article, apply the grouting of seamless tiles). But even if the tiles are laid as close as possible to each other, then the jointing is better to do - this would be a good masking of the tonal differences between the tiles and joints. With particular care, choose a putty, it must be flexible and have high adhesion. Grout is always matched to the tone of the tile, so you can hide the seams as much as possible.

If you set out to completely get rid of the seams, then the rectified certificate is not the only and not the best way out. If you take large-format plates, and there are also 3x1.5 m in size, and they cover them with a small room, for example, a bathroom, then there will be practically no seams. But this is too expensive a cladding option, and to do it alone is unrealistic. Therefore, the maximum visual monolith can be achieved only in the case of using processed porcelain. If you carefully study our recommendations and follow them, then a “seamless” interior is provided to you.

↑ Differences between seamless ceramic tiles and ordinary

Ordinary ceramic tiles have small roundness around the perimeter. It is they that contribute to the formation of the seam during installation, no matter how tight the tile is located in relation to one another. The seam in any case will be clearly visible. When facing, a pronounced tile pattern is formed.

To obtain rectified tiles for seamless laying during production, all its edges are trimmed using special equipment that ensures strict straightness to the edges of this facing material.

As a result, it becomes possible to lay tiles with a minimum seam (0.5-1.5 mm). The question arises: why is it a “seamless” tile? The answer is simple: seamless - this is not the complete absence of an inter-tile seam in the lining, but the visual effect of its absence. As a result, the tiled floor looks like a single canvas without noticeable seams.

Worth paying attention to!

The use of a seamless laying method implies a high qualification, since even slight deformation or shear can lead to destruction and chips of the ceramic surface. Deciding on the independent performance of such work, you need to soberly weigh your capabilities and abilities.

↑ How to prepare the base for laying

The surface of the base on which the seamless tile is laid requires careful preparation. It is necessary to bring it to a perfectly even state. Any protrusions, cracks and dips are not allowed. All this must be eliminated. For proper preparation of the base and its alignment, it should be noted that:

- sand used for cement-sand mortar must be sieved, without the content of large fractions,

- when buying cement, you need to pay attention to the production date. It is worth acquiring only "fresh" material. Over time, cement loses some of its inherent properties, and if the brickwork does not suffer from this, then for the high-quality performance of a seamless tile coating this is a very important point.

It must be remembered that seamless ceramic tiles should not be used in rooms where there are sharp changes in temperature. It is not suitable for the device under her system "warm floor". Tiles between which a tiny distance are simply deformed and cracked by significant temperature fluctuations.

Laying seamless tiles requires high craftsmanship and accuracy, so it is better if an experienced specialist performs it.

A wooden base is not suitable for such tiles. It is removed and a concrete screed is made. By the way, it is an ideal option for this flooring. The unsuitability of wooden surfaces in this case is due to their high sensitivity to any humidity fluctuations. When the elements of wood are dried or waterlogged, the adhesive layer is deformed, which leads to the same result and the laid tile, which eventually cracks.

↑ Technology for laying seamless ceramic tiles

We found out that only tiles that do not have bevels along the edges are suitable for seamless laying. The main difficulty lies in observing the mirror evenness of the surface of the laid tiles. Even a difference of 1-2 millimeters can spoil the appearance of the coating.

In principle, the seamless method of tile flooring is not much different from the more usual laying of tiles with seams. Before gluing a seamless tile, it is worth taking care of the selection of a tool for work. You will need:

- level,

- notched trowel,

- drill with a nozzle,

- Master OK,

- sponge,

- rubber mallet

- knee pads (when laying, you have to kneel for a long time and a lot).

For seamless installation, it is recommended to use professional grouting and adhesive mixtures, strictly adhering to the technology

We list the main stages of laying seamless tiles, which are carried out after the preparation of the base:

- The surface for laying is marked, the place where the first tile will be laid is selected.

- Glue is being prepared (strict adherence to the attached instructions is mandatory).

- Then the glue is applied to the concrete base and spread evenly over the surface using a notched trowel.

- Lay the tile, previously applying a thin layer of glue on it. It is important to ensure that it lies evenly, without voids. Pressing it firmly to the base, lightly tapping it with a rubber hammer, which allows you to achieve the necessary evenness of the surface of the cladding.

- The laid tile is checked by level. Then, close to the first, the second is placed. Again watch the level. Such an algorithm is followed until the entire tile floor is completed.

It is important to ensure that under the tile there are no areas where there is no glue. Condensation builds up in such voids, which will subsequently cause the tiles to crack on the floor. You can avoid such problems if the facing is strong, and at the same time, gently press the tile.

When the glue dries, it is recommended that the joints on the floors be tiled. The flooring involves wet cleaning, therefore, to protect against moisture under the tile, it is advisable to do this. Grout is selected in the color of the coating. It is better to use one that is resistant to mold. With a spatula it is applied to the surface of the tile and rubbed with a sponge. After filling the joints with grout, the excess mass is removed with a sponge moistened with water.

↑ Advantages and disadvantages of seamless styling

Advantages: without visible seams on the floor surface, this installation looks very attractive. In addition, this circumstance prevents the accumulation of dirt, moisture and fungus at the joints of the tiles.

Disadvantages: taking into account that the production of tile is serial, sometimes it is necessary to adjust the tile by grinding the edges to ensure evenness of laying. And this may require a considerable amount of time and labor.

To obtain the perfect result, taking into account all the pros and cons, in the process of laying seamless ceramic tiles, strict adherence to technology is required

Using the method of seamless tile laying for flooring, you can create, without exaggeration, masterpieces, embody any design ideas.

Characteristics

Laying such a floor covering requires a high professionalism, a considerable share of patience and a lot of experience in carrying out this kind of work. Installation of a seamless floor tile implies high accuracy of masonry, since there are practically no seams here, and it is impossible to compensate for small inaccuracies at their expense. But, due to the lack of seams, the floor design becomes more attractive. For the same reason, the amount of pollution is reduced, since there are no gaps that accumulate dust and dirt, as well as mold and fungi.

Like regular, seamless ceramic floor tiles are available in series. Therefore, with a high degree of probability, the sizes of each fragment will differ in some deviations. In this regard, there is a need for grinding the edges of the material. This is done to obtain the perfect surface and to fit each element to a specific size. Such polishing can take up to 40% of the time from the entire installation process, so it is almost impossible to call it fast.

The laying process itself is notable for the difficulty of fitting each element, which requires absolute accuracy. Any slight displacement during laying of at least one element creates the prerequisites for the violation of the configuration of the entire floor surface after laying one of some rows. All this suggests the need for strict adherence to the technology of laying such tiles and the inadmissibility of any deviations.

Preparatory stage

All works of a preparatory nature, as well as the laying of seamless tiles, are carried out according to the same technological methods as for ordinary tiles. The installation of this cladding material can only be carried out on a level foundation with sufficient strength. Such a foundation can only be a concrete floor, the surface of which must be leveled, filled with a screed to eliminate defects on the surface, after having previously cleared it of debris. The presence of any protrusions, cracks and dips is an unacceptable phenomenon, so all of them must be eliminated.

The screed can be either a regular sand-cement mortar prepared by hand, or a finished mixture diluted with water in the required proportion. The base under the screed must be previously cleaned of dust and dirt.

For the technically correct preparation of such a base, the leveling method should sift the sand for the solution in order to remove large fractions. When purchasing cement, it is necessary to take into account the date of its production, since over time it loses some of its properties. If this is not essential for masonry, then a seamless tile coating on such a solution can sag over time.

The use of ceramic tiles without seams is not possible in rooms where sharp temperature changes are observed. It also can not serve as a coating for the so-called underfloor heating with electric or water heating. On a floor heated from below, tiles with a minimum gap between them undergo deformation and crack.

Floor insulation with waterproofing material

Often, especially in private houses, there is a need for insulation of concrete floors. Therefore, this operation should also be classified as preparatory work before laying seamless tiles.

To carry it out, a roll-type waterproofing material is laid on the floor. This may be a membrane, glassine coating, polymer film and the like. With a sufficiently large floor area in one strip, it is impossible to close it. In this case, they overlap the strips so that they overlap each other by 10-15 centimeters, fastening the joints with tape. In this case, you should definitely wind the edges of the strips on the walls to a height of up to 10 centimeters.

Next follows the laying of insulation. His choice is huge now and the acquisition of the necessary material will not be a problem. If the choice fell on a porous heat insulator, then it will be necessary to lay on it another layer of waterproofing material. If it has a high density, then the screed can be filled on top of this insulated layer.

In this case, the screed requires thorough thorough drying, and tile laying on it should begin after five or seven days.

Tile installation

As already mentioned, sticking seamless tiles is completely similar to the usual installation procedure for any other types of tiles. It consists in marking the surface prepared in advance, determining the place where the first element will be laid and in soaking the material.

Then, the preparation of the adhesive composition is carried out, which should be applied to the base for uniform distribution with the help of a notched trowel of the same thickness over the entire plane. Tile glue is very flexible, but quickly hardens, so in order to avoid drying out, you need to cook it in small volumes.

Then follows the installation of the first tile on the floor. It must be accurately placed in the selected place and aligned horizontally. After that, it is pressed by light blows of a rubber or wooden hammer on the front surface.

The laying of the following elements is carried out in such a way that each subsequent tile is firmly pressed to the previous one. In this case, after laying each fragment, the entire surface is checked for alignment and horizontalness using the building level. If the interior of the room contains protruding parts, columns, pipes and the like, technological or architectural "complications", then you will have to cut the tile under their profile.

As for the need to mash such a floor, it is absent due to the lack of seams, which is another peculiar advantage of a seamless tile. However, some experts believe that even with the most experienced master, the laying of the material still can not do without gaps, even the most meager. Therefore, they still use a grout to get rid of the smallest flaws. In this case, grout should be selected according to the color of the ceramic floor to create a monolith effect.

After the glue dries, those masters who see the need for this, proceed to the treatment of the joints with tile grout. Since the floor covering will subsequently be subjected to wet cleaning and, consequently, the possible ingress of moisture under the tile layer, this operation makes sense. Grout, as already mentioned, is selected in one color with a coating, and its best grade will be one that is resistant to mold.Grout with a spatula is applied to the surface of the seamless tile and rubbed with a sponge, and after filling the seams with it, the excess is removed with a sponge dipped in water.

During the installation process, it is necessary to ensure that under the laid tile there are no areas where there is no glue. Such voids become places of accumulation of condensate, which over time leads to cracking of the tile. Therefore, in the process of cladding, it is necessary to press this tile strongly, but carefully.

Patterned styling methods

Today, there are many different schemes for laying tile coverings, but not all of them can be used for their seamless installation. This is because the formation of a periodically repeated pattern occurs precisely due to the seams. The formation of exquisite patterns using a seamless styling method is achieved due to the contrasting textures of marble, porcelain stoneware and other materials.