The classic wood fireplace gives the house a unique cosiness and charm, but many consider it to be too expensive a pleasure, believing that laying a fireplace with your own hands out of brick is a job for professionals.

Do-it-yourself brick fireplace

In fact, this task is not so difficult, it is enough to find a suitable drawing or arrangement diagram, stock up on material, and a real fireplace with crackling firewood in it will appear in your house.

Choosing the size and shape of the fireplace

Any construction work begins with the project, and before proceeding with the construction of the fireplace, you need to determine the size and shape of your hearth, because not only its appearance, but also your safety depends on them.

What fireplace sizes are considered ideal? A clear answer to this question does not exist, you will have to focus on the size of the room, the classic proportions and the standard size of the brick.

- We determine the dimensions of the furnace. To do this, measure the area of the room and divide it by 100. For example, for a living room of 30 square meters, a combustion chamber area of 0.3 meters is enough.

- Find the depth of the furnace. With respect to its width, the depth should be 1.5-2.5 times less. So, for a selected firebox area of 0.3 meters with a depth to width ratio of 1: 2, the depth will be 37.5 cm - one and a half bricks, and a width of 75 cm - three bricks.

- Find the height of the furnace. It should be 1.5 times greater than the width: for a furnace with a width of three bricks, we take a height of just over a meter, which corresponds to 14-15 rows of masonry.

- We determine another important parameter - the area of the smoke hole. It should be related to the furnace area as 1:10 or 1:15. The chimney itself can be slightly wider, while the height of the straight section should not be less than 3 meters and more than 5 meters, otherwise it will be difficult to achieve stable traction.

The easiest way is to use ready-made drawings of brick fireplaces - in this case you do not have to draw a layout yourself and you can avoid unpleasant surprises when kindling. From the proposed options you have to choose the most suitable fireplace in size and shape, after which you can buy material and get to work.

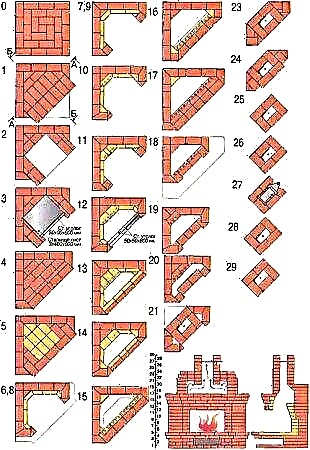

Ready-made ordering schemes

- A brick corner fireplace is usually installed in a small living room or bedroom, because it saves space, while effectively heating it. The layout of such a fireplace is shown in the figure. The size of the fireplace is 1x1 meter. The outer walls are made of ceramic red brick (2 hundred pieces), the firebox is made of refractory bricks (1 hundred pieces). In addition, you will need clay and sand, cement, concrete for the foundation.

Step-by-step diagram of ordering a brick fireplace - photo

Simple layout of a brick fireplace

- red ceramic brick - 300 pieces,

- fireclay brick - 130 pieces,

- kiln clay or refractory masonry mixture - a pair of bags,

- quarry sand - 4 bags,

- cement - 1 bag,

- metal corner and steel strip - 3 pieces of 1 meter each,

- stove door for cleaning the chimney,

- stove damper.

The layout of the brick fireplace in the English style and its dimensions are shown in the figure.

Diagram of an English brick fireplace with a direct chimney - photo

The general methods of masonry fireplaces are very similar, so the most difficult option is considered in the article - an English brick fireplace with a slanting hood. You can learn about how to fold a corner fireplace from a brick from an article about corner fireplaces, and laying a simple fireplace for beginners should not cause difficulties if you carefully study our recommendations.

Fireplace Foundation Requirements

The stability of the fireplace depends not only on the masonry, but also on the reliability of its base. The foundation for the fireplace must be poured separately from the foundation of the building, otherwise, with seasonal ground shifts, damage to the hearth and chimney is possible. If the fireplace is installed near the load-bearing wall, between the strip foundation of the house and the base of the fireplace, a compensation pillow is made of sand - it is filled up between the foundations and spilled with water.

The height of the base under the fireplace should be such that the first row of masonry is at the level of the finish floor. The foundation pit can be shallow, while sandy-gravel cushion with a thickness of at least 0.5 meters is necessarily performed on heaving soils. A layer of sand and gravel compensates for soil shifts and prevents the capillary rise of water from it, which provides waterproofing of the foundation itself and the walls of the fireplace.

The foundation is poured from concrete M150-M300 with mandatory reinforcement. Formwork is made of boards or plywood, fastening the shields with self-tapping screws. The size of the foundation to be poured should exceed the size of the fireplace on each side by 10 cm. Drawings of brick fireplaces, as a rule, contain the necessary dimensions, and you can safely use them when pouring the foundation.

After pouring the foundation, it is necessary to withstand concrete until the critical strength is set for about 5-7 days, after which you can start marking and laying the fireplace, after laying a double layer of additional waterproofing - roofing felt.

Masonry fireplace + instructions and video

Laying a fireplace in the English style with a direct chimney is strictly according to the scheme. Before masonry begins, the wall behind the fireplace is thermally insulated with a metal sheet or thick foil, and wooden structures are additionally treated with a fire-retardant solution for internal work. You should also take care of the fireproof floor covering in front of the fireplace, where sparks and embers can get in.

Brick fireplace masonry - photo

Before masonry begins, bricks are sorted, laying off those that have cracks and chips. They can be used for laying the foundation. Before each stage, it is convenient to lay out the bricks dry, cut them, sand them.

The red ceramic brick before masonry is briefly soaked in water, the refractory brick cannot be wetted, dust and dirt are washed off with a damp cloth. This measure contributes to a more uniform drying of the masonry mortar. The order of the brick fireplace with explanations is shown in the figures.

- The base of the fireplace (rows 1 and 2) is made of red solid brick. Its area is 1140 by 1270 mm, two rows of masonry with dressing. Before laying, it is necessary to check the foundation for level, if necessary, small irregularities can be leveled by increasing the thickness of the seam. The foundation is laid on a cement-sand mortar, the ratio of cement to sand is 1: 2 - 1: 3. Rows 3 and 4 are laid out similarly according to the scheme, while the bottom of the furnace in the 4th row is made of refractory bricks for a fire-resistant solution. The ratio of clay and sand should be such that the solution does not adhere too much to the trowel or putty knife, but also does not slip from it.

- The next stage of laying the fireplace is the implementation of the walls of the furnace. They are laid in accordance with the order, with the inner walls laid out of refractory bricks on the clay mortar, the outer walls are made of ceramic bricks, on cement-sand mortar or on a mixture of clay and sand with the addition of 10-20% cement. The bricks forming the rear corners of the furnace are cut diagonally by the grinder. This form of the furnace contributes to better heat transfer.

Ordinary masonry of the fireplace - the first 4 rows

Ordinary masonry of the fireplace - 5, 6, 7, 8 row

Ordinary laying of a fireplace 13-16 row - photo

Masonry fireplace 17-20 row

Bricklaying of a fireplace 21-26 rows

General information and device

In fact, a traditional English fireplace is a simplified stove, consisting of the following basic elements:

- a large open firebox in the form of a rectangular niche (portal), made of solid ceramic bricks, the straight chimney shown in the diagram is equipped with a special protrusion - a chimney tooth and a tapering part - a smoke collector, a pre-heating frontal platform plays a decorative role and at the same time protects the floors from sparks from firebox, valve for adjusting traction.

Note. In simple designs, grates and an ash chamber are not provided, firewood is burned directly on the brick hearth.

In the current conditions, fireplaces are built solely to create a unique atmosphere of comfort in private homes and cottages, and not with the aim of organizing heating. The fact is that open foci are extremely ineffective, even for more complex models with two smoke circuits, the efficiency does not exceed 20%, since the lion's share of the heat simply goes outside through the pipe.

Scheme of a complex fireplace with two smoke circuits

The room is heated due to infrared radiation emitted by an open flame. As soon as it fades, heat transfer stops. Convective heating does not work here - the draft of the chimney, which has a large cross section, literally sucks the heat out of the room along with the air flow. It is impossible to reduce the transverse size of the chimney - the fireplace will smoke into the room. For the same reason, brick walls practically do not accumulate heat.

Tip for calculating the size of the outbreak. When building fireplaces with your own hands, it is important to achieve a compromise between the smoke of the room and too strong draft, which helps to remove heat with air. The cross section of the chimney should be 1/9 of the area of the open part of the firebox (portal). In turn, the dimensions of the frontal opening are taken in the ratio of 1/50 to the area of the room, and its height is 1.5–2 times greater than the depth of the furnace.

So that you can correctly choose the dimensions of the fireplace, without delving into calculations, we present a table with the dimensions of the main elements tied to the area of the room.

Instructions for laying the fireplace

On various Internet resources and in the technical literature it is easy to find a variety of projects of home and street centers, accompanied by orders and photos. But at the heart of all the proposed designs is a traditional English fireplace, which we offer beginners to put. As an example, let’s take a look at the relatively small model shown in the drawing and designed for a room with an area of 20-25 m².

Note. If your room is different in size, then the dimensions in the drawing can be changed in accordance with the table, only to adjust them more precisely to the length and thickness of the brick (taking into account 5 mm joints).

Step-by-step work stages are as follows:

- Preparation - the choice of a place for the future outbreak and the purchase of building materials.

- The device is a reliable foundation - reinforced concrete or brick foundation.

- Preparation of mortar and masonry.

- Test ignition and warming up.

By design, fireplaces are divided into wall, corner and built-in. We chose the first option because of the simplicity of execution - the construction is being built next to the existing wall. It is much more difficult to make an angular model without proper experience, and to embed the structure in the partition, the latter will have to be disassembled.

The optimal location of the hearth is near the internal load-bearing wall or partition, closer to the center of the room. At the same time, try not to complicate the passage of the chimney through the roof - make sure that it does not hit the ridge. On both sides of the fireplace, you must provide at least 1 m of free space along the walls. The worst place for the hearth is near the outer fence or next to the doors.

Tip. Too small rooms up to 12 m² are not recommended for fireplaces. Moreover, it is not allowed to build them in apartments of multi-storey buildings. The way out is to install a gas or electric fireplace insert and make the lining of decorative brick and drywall, as shown in the diagram.

Necessary building materials

To independently lay down the fireplace according to the above drawing, it is necessary to prepare the following materials:

- full-bodied ceramic brick - 300 pcs., fireclay (brick) brick - 120 pcs., chimney damper, dry mortar for refractory masonry - 150 kg, ready-mixed clay-sand mixture for laying stoves - 250 kg, metal equal-angle corner 50 x 3 mm - 2.5 m, revision oven door.

Red ceramic brick grade 150-200 - the main material used in the furnace business. Choose a solid stone of standard sizes 250 x 120 x 65 mm without cracks, preferably with smooth sides. Building materials of poor quality and used can not be used for masonry fireplaces.

Fireclay bricks used to form fireboxes for wood and coal stoves are made in different sizes. A stone of ShA grade 250 x 124 x 65 mm is suitable for you. It is laid on a special solution of refractory clay and mortar.

Material saving advice. Ordinary ceramic brick quietly withstands temperatures of 700 ° C, which corresponds to heating when burning wood. Refractory stones, whose price is significantly higher, are designed for a maximum temperature of 1690 ° C. Hence the conclusion: if you do not plan to heat the fireplace hot daily, then feel free to make a combustion chamber from cheaper red brick.

Oven masters are able to prepare masonry mortar from individual components - sand and clay (cement is not added!), Intuitively choosing the exact proportions. Beginners have no choice but to build a fireplace based on ready-made dry mixes sold in stores. If you want to make the solution yourself, we strongly recommend that you first fill your hand in simpler designs. For example, fold a street barbecue or barbecue, choosing the proportions experimentally, to feel all the nuances of working with clay.

Build the foundation

Since the total mass of the brick hearth exceeds 1 ton, a reliable foundation is indispensable. It must be arranged separately from the foundation of the house, having withstood a minimum spacing of 5 cm. If the fireplace is supposed to be built in a lived-in room, you will have to open the floor in a section exceeding the dimensions of the future structure by 100 mm in each direction. For our example, the dimensions of the site will be 137 x 124 cm (according to the diagram above, the dimensions of the building are 127 x 114 cm).

Install the foundation for the fireplace according to the following step-by-step instructions:

- Dig a pit and carefully stamp the bottom. Depth is determined by the existing foundation of the house.

- Lay sand on the bottom and compact again. The total thickness of the pillow is 100 mm.

- Lay the foundation pit to the ground level with a rubble stone. In the process of filling, fill all cavities with a liquid cement or lime mortar mixed with clay.

- Form a flat concrete platform on top and after hardening lay on it 2 layers of waterproofing from an ordinary roofing material.

Note. Fragments of concrete, old brick, shell rock and other piece materials will fit in as a rubble.

The second stage of laying the foundation can be done in two ways: fill in a reinforced concrete slab or lay out the base of red brick. The first option, shown in the drawing, is more reliable and convenient for further construction, since a continuous plate allows you to put the wall anywhere in the site. It is implemented as follows:

- Fabricate and install the wooden formwork to the height of the clean floor of the building so that the foundation slab protrudes beyond the dimensions of the future fireplace by 50 mm in all directions.

- Tie a grid of iron reinforcement with a diameter of 12-16 mm and set it at a height of 5 cm from the roofing material, using small wood linings.

- Prepare concrete grade 150, mixing cement M400, sand and gravel in the proportions of 1: 3: 5. Lay the concrete mixture in the formwork and level the site with the rule of the building level.

After 7 days of concrete hardening, remove the formwork and treat the foundation walls with bitumen mastic.Before you lay out the fireplace, wait until the reinforced concrete slab hardens completely (another 3 weeks), then cover it with 2 layers of roofing material and proceed to the masonry itself. To avoid mistakes when installing the foundation, watch the video from the furnace master:

Fireplace Rules

Laying out a regular wall and a brick fireplace body are two different things. So before you build a home, read the general rules for its construction:

- when making refractory and clay mortar, clearly observe the ratio of dry mix and water indicated on the packaging by the manufacturer, first lay the stones of each row dry, adjust and file according to the procedures, and only then put on the mortar, soak the red brick before laying in place by 3 —5 minutes, until air bubbles cease to appear, observe a maximum joint thickness of 5 mm; Only at various points with a plumb line and a horizontal building level, when installing corners of metal, a number of stones resting on it must be laid without a solution.

Note. Soaking refractory stones is not recommended, but only rinsing with water from dust, because the material gives off moisture for a long time and can burst after kindling.

In the process, bricks can be tapped, but moving in a horizontal plane is highly undesirable. Remove bulging excess solution with a trowel, and wipe the entire wall with a damp cloth to form a smooth surface. For a detailed description of the process, see the next video:

The order of work

First of all, the foundation plate is covered with a sheet of galvanized roofing iron, and on top with basalt cardboard. However, according to experts, the latter is successfully replaced by felt saturated with liquid clay. The required set of masonry tools is shown in the figure.

The first two rows of ceramic brick form the base of the fireplace and the pre-heating area, the 3rd and 4th - the hearth of the furnace. Please note: in order red and fireclay stone is indicated by different colors. The fifth and subsequent rows (up to the 11th) form the walls of the combustion chamber and the outer contour of the portal.

Having laid the 12th row of stones, install the steel corners that serve as the support of the front wall. The following levels form a smoke box and a chimney tooth, which is shown in the ordinal diagram. On the 16th row, a cleaning door is built into the back wall.

The rows of bricks from the 17th to the 23rd form the body of the fireplace, and the remaining 3 levels form a chimney. On the 26th row, a valve is built into it.

Further laying of the chimney is carried out to the desired height according to the same scheme, excluding the passage passage through the ceiling. Here it is necessary to lay out a special extension - cutting, whose task is to protect wooden structures from incandescent flue gases. According to fire safety rules, the combustible floor material must be protected by a 38 cm thick brick wall. All requirements for the chimney pipe, including its height, are reflected in the diagram:

In conclusion - a test kindling of the hearth

After the solution has dried, which will take 10-14 days, make the first kindling. Here it is important to observe one rule: the entire masonry should be warmed up gradually so that no cracks occur. Put a small armful of brushwood or slivers on the hearth, fully open the flap and set them on fire. Next, lay firewood in small portions for several hours, watching the walls of the hearth and chimney. Fix the appearance of cracks - then fill them with the same solution.

The finished fireplace can be decorated in various ways - to plaster, to decorate with tiles with tiles or to paint. Of course, provided that after a full warm-up, it functions properly and the masonry did not produce large cracks. If you did everything according to the instructions and without rush, then commissioning will probably do without problems.

Fireplace calculation

When building a brick fireplace, it is extremely important to pay special attention to the calculation of its parameters. This is due to the fact that it performs not only a decorative function, but is also used to heat the room. First of all, it is necessary to accurately determine the required dimensions of the furnace hole. In this case, it takes into account:

- The ratio between the ax portal and the room size should be approximately 1 to 50. Therefore, if space heating is required, an area of 20 square meters. m., then the size of the furnace should be approximately 0.4 square meters. m

- The ratio of the height and width of the furnace should be in a ratio of 2: 3. In this case, for a room of 20 square meters. m. the optimal size of the sides will be 51 by 77 cm.

- An important indicator is the depth of the furnace. Traction will depend on it. The depth of the furnace should be in proportion to the height of 7:10. Therefore, for such a fireplace, this indicator should be about 34 cm. If the indicator is higher, then heat loss will increase, and if lower, smoke can penetrate into the room.

- The area of the chimney should be approximately 10 times smaller than the area of the portal.

- A podium should be placed in front of the furnace opening, the width of which should be about 50 cm. The side podiums should have a width of not more than 30 cm.

- The transfer sheet must extend beyond the combustion chamber to a distance of 30 cm.

Calculating the amount of material based on these data is quite difficult. This is due to the fact that for different types, sizes and shapes of the fireplace, a different amount of brick may be required.

You can learn more about the construction of a mini-fireplace from a brick with your own hands from the video

Embedded

A feature of this design is that the fireplace is installed inside the supporting wall. Inside this wall, a chimney is pre-mounted. This option is quite complicated, so it is rarely chosen for self-construction. In addition, the creation of such a fireplace is possible only at the design stage of the house.

Wall

The most successful option for self-manufacturing. It can be easily done both in a country house and in a small cottage, without having the experience of building such structures. You can create a wall fireplace both at the design stage, and at any time after the construction of the house. However, if you need to build a fireplace in an already finished house, you must first create a separate foundation.

Wall fireplaces can be either straight or angular. The latter option is the most compact, so it’s great for a small room. Moreover, its construction is much simpler than direct, and much less material is required.

Preparation for construction

The beginning of any construction is the preparation of a sketch and carrying out settlement work. To begin with, you should draw a future fireplace by hand in relation to the room. You should also carefully draw the location of the furnace, the shape of the portal, chimney and other elements. Dimensions should first be specified in advance, and then make calculations using the formulas.

Based on an approximate drawing, a detailed drawing should be made. In it, you need to specify the dimensions of all parts, a side section of the building and other elements. Particular attention must be paid to the ordering scheme by which the construction will be carried out. There are many such schemes. You can choose the best option or think of your own. You can use one of the ready-made drawings of the fireplace, having previously adjusted it taking into account the size and characteristics of the room.

Materials and Tools

For the construction of a brick fireplace, you can use a full-bodied brick, but the interior decoration must be done only with the help of a special refractory brick. Such a material is characterized by a high index of resistance to prolonged exposure to high temperatures and their differences, as well as the effects of chemical components that arise as a result of combustion. In addition, the refractory brick heats up slowly and retains heat for a long time.

To prepare the solution, it is recommended to use a special refractory mixture, which can be bought at a hardware store or prepared independently. The simplest version of the mixture consists of clay with sand. The ratio between the components is calculated empirically. The finished mixture should have a consistency of thick sour cream. It is not recommended to use cement for laying a fireplace. It can be added in a small ratio to a mixture of clay and sand only during the construction of the base.

To prepare a solution for the base or side walls of the fireplace, you can use any kind of sand. For areas that will be constantly exposed to high temperatures, use ravine or quarry sand. River or sea sand is too smooth, so it will have insufficient adhesion to clay. Before preparing the solution, sand should be sieved and washed.

The clay for the solution should be presoaked for a week, mixing daily and adding water if necessary. If there is no time for long preparation of the solution according to all the rules, it is better to purchase ready-made refractory mixtures.

To build a fireplace with a closed firebox, metal doors are additionally required. In order for fire to be visible through them, it is better to choose doors with refractory glass. For a fireplace with an open firebox, no doors are required. You will need a purge and clean door, as well as a flap to adjust traction. For the installation of the chimney, it is best to use a round pipe. You can choose almost any metal, but stainless steel will be the best solution.

For external decoration, you can use decorative plaster, refractory ceramic tiles, decorative stone. In some cases, you can leave the brick without decorative decoration, if the fireplace fits into the decor of the room. For example, for the interior in the loft style.

The construction of a brick fireplace is carried out using the following tools:

- Master OK,

- building level,

- shovel,

- roulette,

- container for mixing the solution,

- Sander,

- plumb.

After preparing the necessary tools and materials, as well as the necessary plans and drawings, you can proceed to the direct construction of the fireplace.

Foundation construction

Before the construction of any type of fireplace, the construction of a foundation under it is required. The size of the foundation should exceed the dimensions of the fireplace by about 25 cm on each side. The depth of the base depends on the weight of the fireplace and its size. For a medium-sized product, a base depth of 50-60 cm is sufficient.

The first step in building a foundation is to dig a hole. After that, the bottom needs to be tamped, after which it is covered with a mixture of gravel and sand. The next step is to install the formwork. For additional reinforcement inside the formwork, a metal grill should be installed. The foundation is poured with a solution for the preparation of which sand, cement and gravel are used. The optimal solution is a proportion of 3: 1: 4.

The foundation completely freezes in a month. After which it can be covered with a cement-sand mixture, and also put a layer of waterproofing. The construction of the fireplace can only begin after the base has completely hardened.

Masonry fireplace

Particular attention should be paid to laying the first row. By rule, it fits without a solution. The brick must be soaked in water immediately before laying so that it does not absorb moisture from the solution.

The first row of bricks should be brought to the floor level. Part of the fireplace above the floor should be at least 30 cm to the firebox. After that, an ash pan and blower doors are installed. The ash pan can be made in the form of a door or a drawer.

After that, the fireplace is laid according to a pre-selected scheme. Flow doors are best made of metal with refractory glass.

The basic principles of the construction of a fireplace

For masonry, you can use various orders, however, any option has common principles:

- the first row of bricks should be installed on the edge, and the next rows should be flat

- the first two rows are the base

- brick should be used without breaks, cracks, chips and other damage,

- if red brick is used for construction, it must first be soaked in water so that it does not absorb moisture from the solution,

- it is not necessary to soak the refractory brick before construction, it is enough to clean it from pollution and wipe it with a damp cloth,

- the thickness of the seam during construction should not be higher than 5 mm,

- if excess mixture appears between the seams, it must be removed before solidification,

- it is necessary to apply a moderate amount of the mixture so that it guarantees reliable adhesion, and does not go beyond the boundaries of the brick,

- during construction, use a homogeneous solution without lumps,

- the solution cannot be used to coat the fireplace inside,

- the best time for construction is summer or another warm period,

- masonry should be started from the corners, so that it turns out to be smooth and neat,

- the bottom of the furnace should be at least three bricks from the floor.

For construction, it is necessary to choose the optimal scheme, purchase high-quality materials and prepare a refractory mortar. It is worth paying attention to the external decoration of the product. After all, the fireplace will become a place around which all family members will gather.