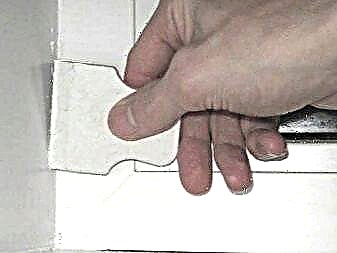

| One-component acrylic sealant STIZ A for the outer layer of the installation joint Application area STIZ A sealant is intended for installation outdoor layer of an assembly seam of window, balcony and stained-glass structures. The sealant meets all the requirements of GOST 30971-2002. To seal the internal circuit, the sealant SAZILAST (STIZ B) is used The properties High vapor permeability of sealant. Specifications. Resistance to vapor permeation, With a layer thickness of 5 mm, m² h Pa / mg, not more than 0.21 (Conclusion NIIMOSSTROY No. 12-07 1110 from 08/28/07) Adhesion to PVC, MPa, not less than 0.1 (NIISF protocol from 06.24.05g) Adhesion to concrete, MPa, not less than 0.1 (Conclusion by NIIMosstroy from 12-07 262 from 03/13/09) Adhesion to wood, MPa, not less than 0.1 (Conclusion NIIMOSSTROY 549 12 00 06 from 04/20/06) Durability, at least, conditional years 20 (Protocol NIISF from 24.06.05g) Elastic modulus at 50% deformation, MPa, not more than 0.05 Main technological characteristics Viability (surface film formation time), h, not more than 2.0 Fluidity at a layer thickness of 2 mm, mm, not more than 1.0 Application temperature range * from - 13 ° С to + 50 ° С Indirect Performance Elongation at the time of rupture, at least 250% (on the blades) Conditional strength at the time of rupture, MPa, not less than 0.15 Operating temperature range from - 60 ° С to + 80 ° С additional characteristics Density 1450 kg / m3 Recommendations for use. 120 grams / linear meter (with a layer thickness of 3 mm and a joint width of 20 mm) Sealant preparation. Sealant STIZ A is completely ready for use. At low temperatures, the viscosity of the sealant increases, so we recommend that the sealant be kept in a heated room for at least 24 hours before use. Surface preparation. Surfaces to which the sealant is applied should be cleaned of dirt, dust, grease, loose particles, cement mortar residues, etc. When working in the winter, clean the surface from frost and frost. It is possible to apply sealant on both dry and wet surfaces. The presence of drip moisture on the surface is unacceptable. Sealant application. In order for the edges of the sealant layer to look even, a construction tape is first glued to the seam, which determines the width of the future seam, then a layer of sealant is applied, after which the adhesive tape should be removed. The sealant is applied to the interface of the panels with a brush, syringe or other device. Recommended sealant thickness should be between 2 and 3.5 mm. The sealant should be applied to the mouths of the joints evenly, without breaks. The width of the contact strip of the sealant with the surfaces of the openings and box boxes should be at least 3 mm, but not more than 6 mm on each side. Packaging. Plastic cartouche - 440 gr. (310 ml) Metallized Folic Tube - 900 gr. (610 ml) Plastic bucket - 7.0 kg. Storage. Transportation. Security measures. Limitations In preparing the page, information was used from the manufacturer, SAZI Company Stiz A (white) 0.9 kg (file package)One-component acrylate vapor-permeable sealant. Application area: The sealant is intended for the installation of the outer layer of the installation joint in the junction of window blocks (including balcony) to the wall openings of heated buildings of civil and industrial construction with a permissible deformation of the installation joint of not more than 15%. For the installation of the inner layer of the installation joint, we recommend using the Styz B. Sealant. For the installation of the additional layer of the installation joint, we recommend using the composition Stiz D. Benefits: ✓ High vapor permeability ✓ Applicable at negative temperature ✓ It has good adhesion to concrete, PVC, aluminum profile, wood, brick ✓ Resistant to UV radiation, weathering and deformation. ✓ Easy to apply Specifications:

|